This is an old revision of the document!

Table of Contents

SPACAR Light FAQ

1. Number of beams per flexible element

For accurate results, it may be necessary to model flexible elements using more than one beam. Whether multiple beams are needed depends on the particular load case and the deformations involved.

Additional beams bring additional degrees of freedom, so that e.g.

- more complex mode shapes can be modelled,

- the deflected shape (in particular for large deformations) can be modelled more accurately,

- a more accurate stress distribution can be obtained.

This means that there’s no general answer to the number of beams that are needed per element. The approach to deciding on the number is to investigate if the quantity of interest (displacement, eigenfrequency, stress, stiffness, etc.) changes with an increasing number of beams. By increasing the number of beams until the quantity of interest doesn’t change anymore, it’s likely that the solution has converged.

The number of beams that are used per element can be set using the eprops(i).nbeams field. See the full syntax list.

For an entirely rigid element, there is no benefit to using more than one beam.

Specifics for the ME module 8 mechatronics project

- For motion in the DOF (the actuation direction of the mechanism), it is likely that the deformation, stiffness, stress and eigenfrequency can be predicted sufficiently accurately with a single beam per flexible element. (You can investigate this using the approach described above.)

- For higher mode shapes, associated with motion in a constrained direction of the mechanism, it is likely that multiple beams are needed per flexible element. A good starting point would be to use

eprops(i).nbeams = 3and investigate if this is enough (i.e. check if the eigenfrequency of interest doesn’t change when further increasing the number). - By default, Spavisual only shows the first 10 mode shapes of the mechanism. To increase this number, see the use of the

opt.customfield in the full syntax list. - Increasing the number of beams leads to more degrees of freedom and more eigenmodes (with generally higher eigenfrequencies). The state space and transfer function representations will contain many states. If possible, avoid unnecessary conversions from state space to transfer functions.

- To use such a detailed model in Simulink, pre-process the state space representation to discard eigenfrequencies higher than the Nyquist frequency. See the project lectures for details.

- Add some modal damping (a relative damping of 0.001 to 0.01 for steel materials) to the modes for more representative Bode plots. See the use of the

opt.transferfield in the full syntax list.

2. Overconstraints could not be solved automatically

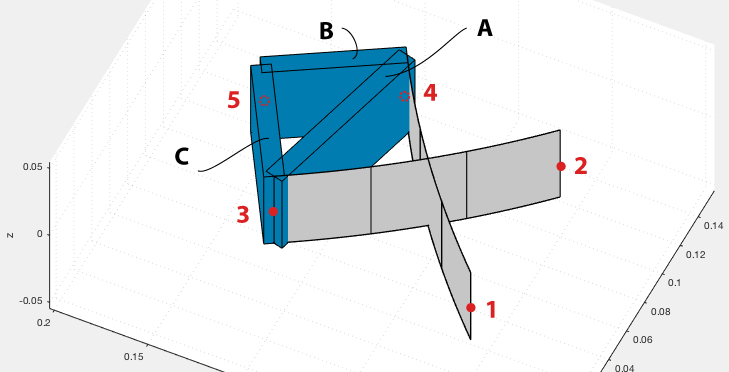

It is most likely that this error occurs because the model contains loops of elements that are completely rigid. See the figure below for an example.

Here, we tried extending the frame by adding a fifth node and two extra rigid elements (B and C). We did this so that we can attach some mass and apply a force on node 5. When running the model, an error now occurs: “Overconstraints could not be solved automatically; partial release information is provided in the output”.

The program is unable to deal with the loop that is created by the rigid elements A, B, and C. With flexible elements, it’s fine to create loops — it’s only rigid loops that should be avoided.

Solution

Remove one of the elements that make up the rigid loop. In the case of this example, we could remove either element B or C — and it would not change the model! Element A still provides the rigid connection between the leaf springs, and we only need B or C to extend the frame towards node 5 in a rigid manner. Visually, it may look a bit different, but structurally, the model is the same. Note that if you’re specifying a density for these rigid elements, the elements also contribute some mass and inertia, so, then, leaving out an element would change the model. In our example, we chose to have rigid elements with zero density (so, massless); we’re placing the relevant mass of the frame in node 5 (using node properties) instead.

Notes

Ground loop: In this example we created a loop using three rigid elements. Note that the fixed world could also be a part of the loop. For instance, modeling just a single rigid element with both nodes fixed would lead to the same error.

Automatic detection: If you’re running MATLAB R2021a (or higher), an extra feature will be available that tries to detect if rigid loops are present. If detected, the nodes involved in this loop will be listed, so that it should be easier to identify the loop.

Manual releases: An alternative solution is to provide appropriate releases for the deformations in the opt.rls field. This way, you can have loops of rigid elements. A future article may detail how to do that exactly …

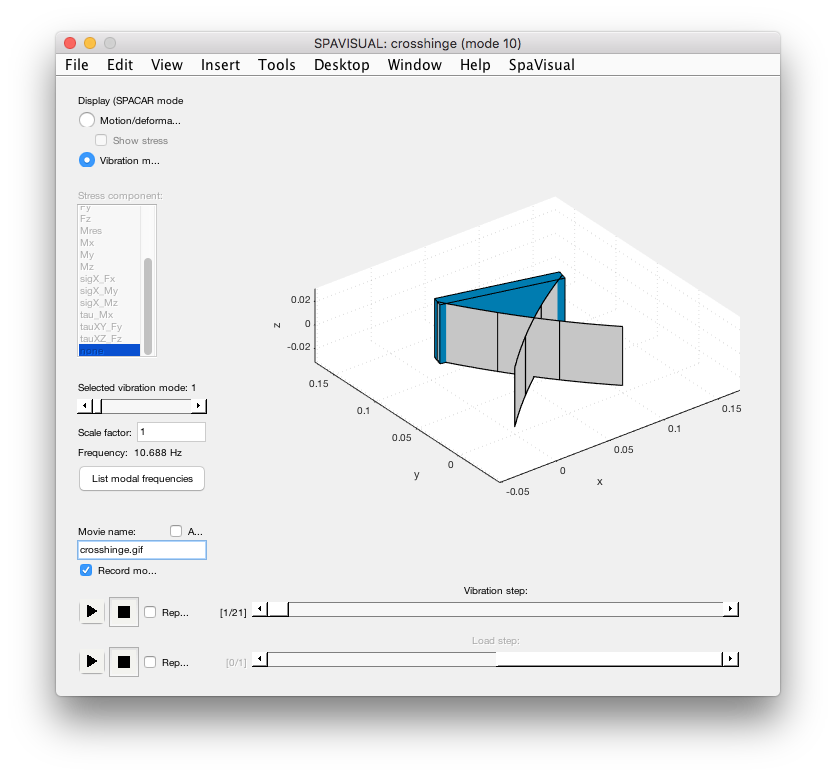

3. Animated GIFs of mode shapes

For presentation purposes, it can be helpful to create an animated GIF of a visualization in Spavisual. You can make a GIF for a particular mode shape or for the general motion of the system. In the Spavisual window, deselect the 'Auto' checkbox for 'Movie name' in the left bottom corner. Select the 'Record movie' checkbox and enter a filename with the extension '.gif'. Then, after clicking the play button for the relevant slider, the animated GIF will be created in the current folder.

Depending on the purpose, you may want to change the appearance of the Spavisual axis in which the model is animated. Sometimes, it could be nice to disable the grid lines or disable the coordinate frame altogether. To do so, add some of the following lines:

% ... model definition ... out = spacarlight(nodes, elements, nprops, eprops, opt); ah = out.fighandle.Children(1); %get the handle of the Spavisual axis axis(ah,'off'); %disable axis (the background in the GIF should become transparent!) %grid(ah,'off'); %disable just the grid lines